History of Stirlingshire

Chapters on Iron Industries & Mining, from “The history of Stirlingshire”, Volume 2, 1880. By William Nimmo

Iron Industries

Early in January, 1760, the first furnace was blown at Carron. Dr. Roebuck, who was the founder of these works, which, with the exception perhaps of Coalbrookdale, are the oldest of any importance in the country, was also manager until 1773; when, getting overwhelmed in difficulties, from the flooding of his mines, he was obliged to sell out; and, in that same year, the company received a charter of incorporation by which its capital was fixed at £150,000.

Roebuck's father was a manufacturer of cutlery in Sheffield. The son studied medicine at the University of Edinburgh, and afterwards graduated at Leyden. Returning to England, he ultimately turned his attention to the chemical and metallurgical arts, and, along with Mr. Samuel Garbett, became a manufacturer of sulphuric acid in the village of Prestonpans. Here he got acquainted with Mr. William Cadell of Cockenzie, who was anxious to engage in the production of iron, and a company for that purpose was forthwith organised, consisting of Roebuck, his brothers Thomas and Ebenezer, Samuel Garbett, William Cadell, sen.; William Cadell, jun.; and John Cadell. The leading articles by which the works, even at the outset, got a world-wide fame, were the cannons, mortars, and chain-shot manufactured for the arsenals of Europe. Ordnance, mortars, and carronades were sent out to Russia, Denmark, and Sardinia; while the latter country received, in addition to a quantity of extra large mortars, a shipment of guns ten feet in the bore. The British Government, however, were by far the most extensive purchasers - the whole battering train of the Duke of Wellington having gone from Carron. The last order for guns came from France. Not since 1852 has there been a single carronade moulded; and this war-casting, which had its name from the works, has in fact become obsolete. It was cast solid in an upright position, and afterwards bored to the required calibre.

It was undoubtedly an unequalled superiority of material and workmanship that gave this establishment unrivalled fame, both at home and abroad, and induced many distinguished men to pay it a visit. In 1821, Prince Nicholas, afterwards Emperor Nicholas, went over the foundry, and was followed by Prince Leopold and Prince Maximilian of Austria. The latest royal visitor was the Prince of Wales, who, in July, 1859, inspected all the chief departments of Carron; and, as an illustration of the moulder's work, the casting of a common three-legged pot was shown him, the patterns for which consist of nine pieces - two for the body, three for the feet, and two for each of the ears. But, one Sunday afternoon, another prince - the prince of Scottish bards - knocked at the Carron gate. Need we further mention his name? Burns, the Ayrshire ploughman - the poet whom all Scotland delights to honour. No admittance, however, could that day be granted the "Great Unknown." So with a diamond, and a stroke of keenest satire, he scratched the following verses on a window-pane of the neighbouring inn :-

"We cam' na here to view your warks,

In hopes to be mair wise;

But only, lest we gang to hell,

It may be nae surprise.

But when we tirl'd at your door,

Your porter dought na hear us;

Sae may, should we to hell's yetts come,

Your billy Satan sair us."

It is generally allowed that the lines were first seen by Mr. Benson, a traveller to Carron Company, who immediately copied them into his order book, and afterwards penned the following reply - Burns having applied for admission incognito.

"If you came here to see our works,

You should have been more civil,

Than give us a fictitious name,

In hopes to cheat the deril.

Six days a-week to you and all,

We think it very well;

The other, if you go to church,

May keep you out of hell."

An unlimited command of mineral resources, together with the readiest channels of export, have always been highly advantageous spokes in the Carron wheel. Now, as in days bygone, the company have rich and extensive workings, both in coal and ironstone, the "hands" of which, from their numbers, form several well-populated villages. Upwards of a century ago, they opened a pit in the parish of Kilsyth, where the ironstone strata have been found from four to fourteen inches in thickness. The coal in the neighbourhood of the works, which dips, for the most part, to the south-east, has been wrought for ages. It is of various qualities. Some of it, being brittle, falls to be chiefly used for the furnaces and forges; while other sorts burn clear, giving a good heat and cake, so that the very dross is valuable. At one time, the company held an enormous quantity of pig-iron, which was made and stored under Mr. Joseph Dawson's managership. A workman concerned, alluding to one of the immense piles, received the following characteristic reply from plain "old Joe," - "Gang on, man, ye're a lang way frae the roof yet," referring to the sky. In 1872, however, when the revenue demanded the best appearance possible, this "sunk capital " was thoroughly cleared out, and realised in cash.

By water, as by rail, the company are at no loss either for the bringing in of raw material, or the throwing out of manufactured goods. A railway, which was laid down some twenty years ago, stretches from the interior of the works to Burnhouse, where it meets the Polmont branch of the North British line, connecting with that of the Caledonian on the west; and where a large basin also adjoins the Forth and Clyde Canal. On this railway one or two powerful locomotives are kept ploddingly at work, while others do gigantic service in coal traffic between the outlying pits and furnaces. What changes come about with time! It is scarcely sixty years since the rails leading from Carron to the Bainsford basin were laid, and even that enterprise in its day was considered no mean undertaking. The first line, stretching from Kinnaird colliery into the interior of the works, was constructed in 1766. The rails in that instance were of wood, covered with a sort of hoop-iron. In the course of the following year, however, rails wholly of iron were got from Coalbrookdale. Six magnificent screw-vessels, that sail from Grangemouth, are likewise owned by the company, and carry the produce of the foundry to London, for the extensive warehouse there; but large quantities of freight, are, at the same time, taken from local and metropolitan traders. For the conveyance of goods to the west and east, sixteen lighters, or other small craft, ply on the canal.

Throughout the works, some splendid machinery plays its part in the smelting and manufacturing processes. There are, for example, the patent hammers, in the forging departments, devoted to axle-making; and the stationary engine, of enormous power, employed in the production of blast. The steam-cylinder of the latter machine is 6 feet in diameter, the piston having a stroke of 10 feet. The blast cylinder is 104 inches in diameter, and 10 feet deep. But a gigantic piece of similar mechanism, which was erected by James Watt for pumping work, is also to be seen, in the old "engine-house," wonderfully complete, barring the furrows of oxidation, taking into account that its services have been dispensed with for the last 30 years. This engine, which was constructed on the atmospheric principle, was fitted with 4 pumps, which raised to a height of 36 feet 40 tons of water per minute. Its cylinder was 6 feet in diameter by 8 feet in depth, and the beam about 30 feet long. The steam was supplied by 3 cast-iron boilers, two of which were globular in form. Two of the original water wheels, 5 feet in diameter, and overshot, are still going. One drives a turning lathe, &c.; and the other Smeaton's blowing engine, which was erected in 1766. This engine embraces 4 air cylinders, about 3 feet in diameter, and is so arranged as to give a continuous blast.

But the furnaces are undoubtedly the headquarters of danger. In 1788 there were only eight of these in blast in Scotland, of which four were at Carron, two at Wilsontown, one at Bonaw, and one at Goatfield - the two latter being fired with charcoal. The largest of the kind, however, is that at Ferryhill, in Durham, whose height is 103 1/2 feet, with cubic contents of 33,300 feet. A few years ago, the Carron Company erected three new blast furnaces upon the plan which has so generally commended itself to the experience of the Cleveland ironmasters, who may be regarded as the most skilful, scientific, and enterprising members of their craft in the world. This step was taken on account of the then high prices of pig-iron, which were realizing to some of the larger manufacturers a clear profit weekly of over £10,000.

Notwithstanding the great, and in many instances powerful, competition now connected with the casting departments of the iron trade, Carron is still the iron-works of Britain. And such general public confidence in its various domestic and industrial products, which include grates, cooking ranges, stoves, boilers, kettles, pots, stew-pans, sugar-pans, rain-pipes, &c., is due, no doubt, to the shrewd and devoted conduct of those men who, for the last 120 years, have held successively the onerous position of head of the works. Mr. William Cadell was one of the earlier managers. He was eventually succeeded by Mr. Charles Gascoigne. Getting embarrassed financially, the latter, while in office here, accepted an offer from the Empress of Russia, who wished to have works constructed in her dominions for the casting of guns, shells, and shot, and, taking with him a number of skilful hands, foundries were accordingly erected at Petrozabodsky, and elsewhere in the country. For Gascoigne this proved a step on the way to position and fortune. In course of time he was created a knight of the order of St. Wladimir, had the rank of general in the Russian service, and died worth £30,000. Next in order came Mr. Joseph Stainton, a native of Cumberland, who had been for several years chief clerk in the counting-house of the works. This was a man of great decision of character, and, as is engraved on his monument in Larbert churchyard, "by economy, diligence, and scientific skill, he relieved the company from embarrassment, and placed it in unrivalled prosperity." He died in harness in 1825, at the age of seventy, and was followed in the management by his nephew, Mr. Joseph Dawson, also a native of Cumberland. "Joe," as he was familiarly called, was likewise much respected by the workmen, and controlled the

destinies of Carron for about a quarter of a century - his career terminating in January, 1850, when he had reached his seventy-second year. A brother, Mr. William Dawson, then got hold of the managerial reins, but who did little, from his retiring, "jog-trot" spirit, in whipping the concern into anything like enterprise and progress. Afflicted latterly with partial blindness and other physical infirmities, he resigned his managership, and went to the grave at the ripe age of eighty years. Mr. Thomas Dawson, another brother, was now entrusted with the same responsible duties. Scarcely, however, had he been installed in office, when he took seriously ill and died suddenly. This led, in December, 1873, to the appointment of Mr. Andrew Gordon, than whom none have shown more of energetic and practical oversight.

Although Carron for many years turned a listless ear to the demand for improvement, she no longer rests on her oars in sluggish inertia. Under the late able management, the works have been carried on with a vigour and enterprise which will compare favourably with the most spirited of their modern competitors. Extensive alterations and improvements are at present being executed. The public road on the north side has been diverted outwards with a considerable sweep, and the future boundary of the works at this part will consist of a substantial wall with the chief entrance and offices intervening. Indeed, these are now so far forward that a short time will suffice for their completion. Internal reconstructions are also being rapidly pushed on. The additional space, which the diversion of the road above referred to gives the company, is being allocated for workshops, to take the place of those dilapidated and smoke begrimed buildings which, throughout the rise and progress of Carron, have been scattered over the works without either plan or method. These modernising operations will throw the centre of the vast industrial establishment entirely open, and, apart from the desirable appearance of order, will afford increased facilities both for productive power and the despatch of goods manufactured. The alterations at present contemplated will, according to estimate, cost about £100,000. Above the main entrance to the works there is now a tower with vane and clock. Underneath are the Carron "arms"—cannons crossed, with the motto, Esto Perpetua. Still, the old east gate, with the counting-offices on the south, fronted by a narrow enclosure containing a few stunted and blackened trees, and the "stable-row," humble and retiring on the north, will not soon pass from local memory.

The farm connected with the iron-works is called the Roughlands, and its lands, extending to 400 acres, lie, for the most part, in the immediate neighbourhood. From the well-stocked steading and the Mulloch field, everything necessary in the form of feeding and fodder is got for the foundry horses; but these have been comparatively few since the locomotives were introduced.

The Carron Company are also amongst the oldest merchants of Glasgow. In 1765, they projected Duke Street, for the purpose of obtaining a direct route from Cumbernauld to the city; and, in 1816, acquired ground in Buchanan Street, upon which they erected a warehouse and manager's residence.

An amusing circumstance is attached to the preliminary arrangements for the Carron works. There happened to be one more than the landowner to be bargained with in the feuing of the 14 acres as a site; viz., the fanner, whose lease of the grounds extended over some couple of years. A very reasonable sum was asked for the right of immediate possession; but the demand, from its mistaken exorbitance, could not be entertained. Thus, unable to come to an amicable understanding, the representative of the negotiating firm gave the tenant time to reconsider his terms. In the interim, the farmer had a call from a friend, shrewder, commercially, than himself, who observed that the Englishman had probably mistaken pounds Scots for pounds sterling. And so it turned out; but, just as an explanatory letter was on the eve of being despatched, forward came the company's acceptance, thereby agreeing to pay exactly twelve times the money asked.

From the south is got the most striking impression of Carron, with its ringing industry and flaming furnaces. The latter are a most trustworthy barometer to the surrounding villagers. Should they, in the gloom of night, cast a glowing belt over the atmosphere, the following day is certain to be showery. Opposite the western portion of the works are several heavy hills of ironstone, and as much old metal in patterns as would be a handsome capital for many a smaller foundry; while on the north side of the river, immediately opposite the furnaces, there is an enormous mass of rubbish, called the cinder-hill, and which keeps continually smouldering, like some miniature Vesuvius. Of this mountain of old scraps and ashes - the accumulation of many years - it could scarcely be credited that its every particle, so to speak, had been carted out of the works.

Until lately, the great body of the Carron men were natives of the district, whose forefathers had been in the same service; and, as stock goods were invariably made when a temporary dulness affected the demand for certain articles, few of the employees ever thought of leaving the place. But old men and old customs have passed away. Those now at the head of affairs, in following out the spirit of the age, care nothing for old servants. What is sought for and got is the man who, all through, is cheapest for the masters. The present average rate of wages earned by moulders is 24s. a-week; by pattern-makers, 21s.; by wrights and blacksmiths, 20s.; and by labourers, 15s.

Connected with the works there is a friendly society, which holds an interest, by shares, in the company, and provides pecuniary assistance for its members in days of ill-health or accident. This "club " was founded about sixty years ago, and has a membership of over 700. There are, however, other two principal benefit societies, with a number of minor ones. A cooperative store has also been in existence here for upwards of fifty years, and no similar association could be more harmoniously and successfully conducted. From its start, indeed, it has been exceptionally well kept together, notwithstanding the rival societies in almost every adjacent village. About twelve years ago, the company erected a large and commodious schoolroom for the education of the local children; while, on 2nd October last (1880), the memorial stone of a U. P. church was laid by the Rev. John Yellowlees, minister of the congregation, who was, on the occasion, presented with a silver trowel, bearing a suitable inscription. In a cavity in the wall of the west gable, a glass bottle was deposited, containing the leading newspapers and specimens of the current coins of the realm, over which the stone was placed. The building is of Gothic design, and will, when completed, accommodate about 500 people. Its entire cost is estimated at £1,700, and there is every prospect of the church being opened free of debt. The architect for the work is Mr. James Boucher, Glasgow.

The Falkirk Iron Works, now the second largest in Scotland, were started some sixty years ago by a number of enterprising workmen from Carron, and only fell into the hands of the present proprietors in 1848. From the outset, their progress has been steady, but especially during the last thirty years the development of the foundry in its various branches has been remarkable. The buildings now cover 8 acres of ground, and the employees, numbering 900 (men and boys), turn out over 300 tons of castings per week. Here an extensive trade is done in the ornamental or artistic class of goods; but, during the Crimean war, 16,000 tons of shot and shell were manufactured by the Messrs. Kennaird; while their orders for guns of all sizes, for mercantile ships, are considerable. The firm, with Mr. George Binnie as manager, have also executed several foreign contracts of importance. Amongst these were castings for some of the principal iron bridges in India, Italy, and Spain. But fountains for the Calcutta Water Company, and tubular telegraph posts for South America have likewise been supplied. The weightiest portions of work recently made, however, were the columns for the Solway viaduct. These were cast in 10 and 20 feet lengths, to be bolted together as the complete column. No establishment in Britain can cope with the Falkirk Foundry in its elegant and varied stock of patterns for such goods as the following :- register stoves, hat and umbrella stands, garden-seats, verandahs, iron stairs, statuary groups, mirror-frames, inkstands, etc. A small figure of a stag, browsing, was shown, by the Messrs. Kennaird, at the Exhibition of 1862, along with a variety of other castings, as illustrating the capabilities of the sandmoulding process. In order to have the stag cast in one piece, the mould had to be made in upwards of a hundred parts, each part being simply a clod of moist sand, held together by compression. Sugarpans for the West Indies; grates, pots, and pans for the million, are only a further sample of the great variety of iron goods manufactured here. Few foundries, in fact, have risen so rapidly into fame and importance; and it may safely be affirmed that none show greater promise of being able to "hold their own" in the vast competitive field of iron manufactures.

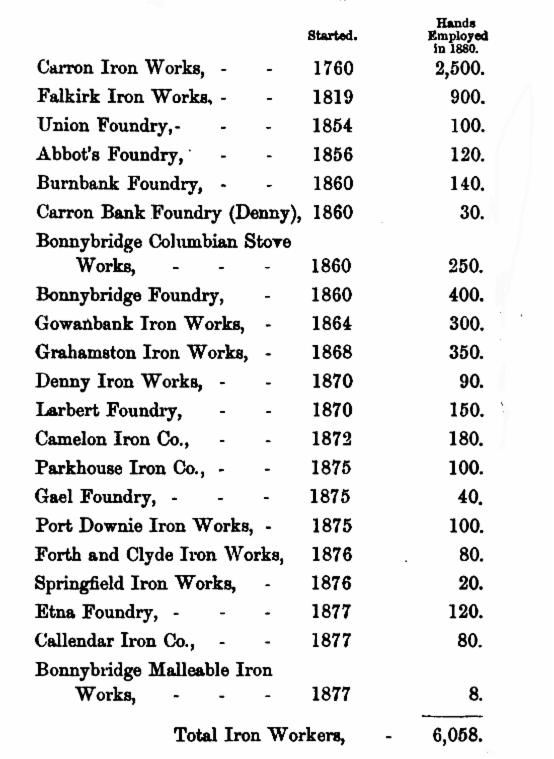

A short distance west the canal bank are the works of the Burnbank, the Gowanbank, the Grahamston, the Parkhouse, and the Camelon iron companies; while at Lock 16 we have the Union Foundry, with the Port-Downie and the Forth and Clyde iron works. In addition to these eight establishments, there are three of recent date to the eastward of the Falkirk iron works. These are the Abbot's, the Gael, and the Etna foundries—the last mentioned being a branch of the Etna works in Glasgow. There are likewise two new foundries situated close to the branch of the North British Railway at Grahamston, the one being called the Callendar, and the other the Vulcan iron works. Here, is also the extensive engineering establishment of the Messrs. Blackadder. The reason of so many foundries having been thus recently started to the north of Falkirk is not far to seek. Middlesbro' "pigs," which are now chiefly used in the manufacture of castings, are brought by steamer to Grangemouth, and thence conveyed per Forth and Clyde Canal to Glasgow (Port-Dundas); while the manufactured goods are also forwarded along the latter route to Grangemouth for shipment to London. Hence the great and double saving in carriage to the Falkirk ironfounders - the distance to Glasgow from Grangemouth being nearly seven times the distance to Grahamston. The following table will show the rise and progress of iron-working throughout the foundry district of the county :-

Nail making was introduced into Camelon, about eighty-five years ago, by Mr. Caddell of Carronpark, who brought workmen from England for the purpose, and thus the trade was taught those belonging to the district. In 1830, there were about 500 nailmakers here; but, in 1833, the cholera cut off so many of this class that Mr. Fairbairn, who had also become a manufacturer, found it necessary to advance £40 against interments, which was repaid from the earnings of survivors. At that period, a man working from 5 to 5 1/2 days a week, and each day consisting of 10 hours, earned from 9s. to 14s. a week, and with a boy under him 14s. to 16s. Latterly, double that money was got; but the machine-made nails from America and London have ruined the hand-made trade. At present there are only about 50 nail-makers in Camelon, of whom Mr. James Jones employs 15, and Messrs. Fairbairn & Co. 8. In St. Ninians, thirty years ago, there were 200, who made from 1,000 to 1,200 nails in the day; but their working hours were long, and their wages small. 8s. or 9s. per week was the most that could be earned. Here, too, for the reason stated with respect to Camelon, the nail trade is of no account. Only some 30 men are so employed.

Mining

Coal, while one of the most valuable of our minerals, is also one of the most abundant, The output in Stirlingshire during 1879 was 967,855 tons - the collieries of the western district producing 257,539 tons, and those of the eastern 710,316. Of ironstone there was likewise raised in the western district 105,947 tons, and in the eastern 2,819; making a total of 108,766 tons. The amount of fire-clay raised, for the same period, was 8,219 tons; and of oil shale, 1,135. Throughout the county, there are at present 34 pits open, the principal of which are in the districts of Bannockburn, Auchenbowie, Denny, Lennoxtown, Kinnaird, Falkirk, Bedding, and Slamannan; while the number of men engaged over all is stated to be about 1,800. As regards the coal-fields of the world, although our own land does not contain the largest amount of fossil fuel, its output is greater than that of any other country. The extent of the coal-fields in Great Britain is said to be 4,251 square miles; while the annual weight raised is now usually estimated as equal to 35,000,000 of tons. The home consumption is stated to be 23,000,000 of tons per annum; and if coal costs the consumer an average price of 7s. per ton, then 23,000,000 tons will be worth in all over ,£8,000,000 sterling. The total number of persons engaged in the work of British collieries has been computed at from 160,000 to 180,000; and that the total capital thus employed is no less than £10,000,000.

The following short calculation will give the results of all that can be conjectured as to the amount of vegetation in coal:- Wood affords in general about 20 per cent., and coal about 80 per cent, of charcoal. Apart, therefore, from the oxygen and hydrogen, it must have required 4 tons of wood to yield the charcoal which we find in 1 ton of coal. Let us then suppose a forest composed of trees 80 feet high, that the trunk of each tree contains 80 cubic feet, and the branches 40, making 120; the weight of such a tree, at 700 specific gravity, will be 2 1/4 tons; and allowing 130 trees to an acre, we have 300 tons on that space. Further supposing the portion that falls annually, leaves and wood, to be equal to one-thirtieth, we have 10 tons of wood annually from an acre, which yields 2 tons of charcoal; and this charcoal, with the addition of bitumen, forms 2 1/2 tons of coal. Now a cubic yard of coal weighs almost exactly a ton; and a bed of coal, 1 acre in extent and 3 feet thick, will contain 4,840 tons. It follows, therefore, that 1 acre of coal is equal to the produce of 1,940 acres (i.e., 4,840 divided by 2 1/2) of forest; or, if the wood all grew on the spot where its remains exist, the coal bed 3 feet thick, and 1 acre in extent, must be the growth of 1,940 years.

It need not be said that the pit as a workroom is peculiarly dangerous. The collier, in fact, must be seen "holing," for the more than common difficulties and perils of his trade to be fully understood. Flat on his side, or down on his "hunkers," or knees, long and laboriously he pikes, working out the block of coal from the wall or seam.

When Bruce, the traveller, returned from Abyssinia to Kinnaird, he was greatly dissatisfied with the way in which his collieries had been wrought. After some stormy disputes with the lessees, he agreed to submit the matter to a committee of experienced coal engineers, who accordingly met at Kinnaird, inspected the mines, and made every endeavour to form an impartial judgment. Conversing one day with those gentlemen, he challenged something which one of them said respecting the condition of the mines; whereupon the engineer said, "If you are not afraid, Mr. Bruce, go down and satisfy yourself on the point by personal investigation." The word "afraid" startled Bruce. "Afraid!" said he in his own peculiarly commanding way; "Sir, do you think I should be afraid to go down into my own mines?" At once he engaged to descend with them, the following day, into the "Carse Pit;" and they as eagerly took him at his word, having secretly determined to punish him for the unreasonable way in which he had disputed many of their statements. "He speaks of Nubian sands," quoth one to another that evening; "we'll show him something worse to-morrow, if I am not mistaken." Next day, accordingly, Bruce appeared at the mouth of the pit; and, after donning a suitable suit, went down with his corps of engineers. The strata were not very thick at the best, and many of the wastes were considerably crushed and fallen in. Walking underground was, consequently, anything but pleasant; nevertheless, as the engineers had arranged, in they went, up one waste and down another, leading the adventurer such a dance as traveller never danced before. All the while the engineers pretended to demonstrate to Bruce the conclusions at which they had arrived. Sometimes the party would be stooping in rectangular form; sometimes wading up to the ankles in wet coal mud; and at other times reduced to crawling on their hands and knees for a quarter of a mile. At one part, the engineers passed through an aperture barely wide enough for themselves, who were men of moderate size, and cruelly narrow for Bruce. He tried the passage, but stuck in it; and had to be extricated by the head and shoulders. Again reaching the bottom of the shaft, the figure which he presented is not to be described. Still, up to the last, he maintained his usual composure, and only remarked that he certainly was surprised at the dirtiness of the wastes.

The Snab pit at Kinneil, with a depth of 1200 feet, is one of the deepest shafts in Scotland. In that Bo'ness district, both coal and ironstone abound; there being some seven or eight principal seams of the former, one of which carries a thickness of 12 feet, and two seams of the latter which is black-band in character. One of the most remarkable collieries in the country was wrought here under water. The strata of coal being found to extend far out beneath the firth, the colliers had the courage to work half-way across the channel. A building, or moat as it was called, half-a-mile from the shore, and taking the form of a round quay, afforded an entrance into the sea-pit; but, ultimately, an unusually high tide came which drowned the whole of the miners.

Pits are apt to become all the more fiery the deeper they are wrought; and, where the area excavated is extensive, special statutory attention should be given to upcast and downcast shafts. Never in the annals of our mining industry has there been havoc to equal the appalling destruction of human life of which the last few years have been witness. Colliers, considering the critical character of their calling, are careless beyond all credence. They may be reasoned with, fined, and even dismissed, for rashly flying in the face of rules specially framed with the object of protecting life and property, but all to no purpose. A manager of one of the largest of the Scotch collieries once caught a miner filling his flask from a barrel of gunpowder, while an oil-lamp with open flame hung from his bonnet. What, however, from the enlightened provisions of modern science, and stricter regard to the most ordinary chemical precautions, pit labour is ever getting less and less perilous to health and life. The Davy lamp, no doubt, is in some measure to be thanked for the now comparative rarity of explosions, such catastrophes generally having occurred from the workman's light coming into contact with inflammable air, or, in other words, hydrogen gas.

And a word with respect to the collier's general health. From his toil, so peculiarly chest-trying, it is easy to see why he so rarely shows the "auld grey frostit head." With an average life of only twenty-seven years, he is little short of a phenomenon at fifty; and when found at that "patriarchal age," is generally a crouching invalid, emaciated and breathless. And the diseases to which he is specially liable are those affecting the respiratory organs. "Housemaid's knee " - an acute inflammation over the knee-pan - is a very painful and common sore throughout his class; but the great hydra of the pit is asthma, with the constant tendency to bronchitis in the winter season, and this ailment not unfrequently ends in enlargement of the liver and dropsy. "Black-spit" is another health-undermining, although not mortal disease comparatively, reaching to such intensity at times that a fluid like tar runs out of the throat. Yet this melanosis, strange to say, seems preventive of other affections of the lungs. Consumption, for example, is never heard of amongst colliers; and its absence from the Hebridean poor has also been observed—people who are continually inhaling a carbonaceous atmosphere from the peat reek of their huts. The tissue of the miner's lungs appears most tenacious of the charcoal deposits. Some years ago, on the occasion of a female body being dissected in the neighbourhood of Falkirk, the surgeon who performed the post-mortem operation could tell at once, from the blackness of the lungs, that the woman in early life had been engaged underground, although thirty years had elapsed from the day on which she left the pit. And we have the same baneful dust ruining the health of the moulders in our foundries. The late Dr. Graham, latterly master of the Mint, on analyzing the lungs of a workman who had wrought at Carron for about forty years, found even as much as a fourth of them pure charcoal.

When the oil lamp was abolished from the mine, asthma and black spit were thought to have received their death-blow. And the tallow now in use has certainly done away, to a great extent, with the lamp-black deposits that have hitherto proved so detrimental to collier vitality. It is, in fact, rare now to find any of the younger pitmen afflicted with asthma, except where the disease may be fairly considered hereditary; and further improvements in pit-lighting are at present being contemplated.

A great deal of nonsense has, of late, been written about the dusky heroes of the mine. Everywhere they have been represented as a brutal, illiterate, and godless class; and it cannot be denied that their conduct, so far from being the genuine embodiment of every virtue, is still in a great measure rude, and perhaps not quite up to the ordinary standard. Yet not so sweepingly can they be written down either barbarians or vagabonds. The great bulk of the men employed in our new collieries undoubtedly lead a most riotous life. Nor is it surprising that we should there find so much of the baser dross of humanity. To these young coal workings, all the unsettled Irish of the country flocked; and whatever wealth of wild goodness may be common to the hot-headed Hibernian, at his door assuredly lies, for the most part, the notorious blackguardism of our mining hamlets. That lower and degraded class too, are without exception itinerants. Never certain of steady employment, they keep themselves in readiness to take up their bed at any hour and walk. It would be well, therefore, if by some arrangement the miner could be made to feel sure of permanent work and a settled home. No doubt there are peculiar difficulties in the way. Colliers, of all the "sons of toil," are specially apt to get dissatisfied and restless. Many of the steadiest hands have to be frequently shifted in their workings; and even sent at tunes into a different pit. By-and-by their power of muscle fails them - their thews and sinews get weakened and worn, and the poor fellows go about, as it were, seeking their lost strength.

As we have already hinted, the general enlightenment and self-respect of the workmen connected with our older collieries are undisputable; while a growing intelligence throughout their ranks is ever raising them in the scale of moral being. From Garscadden, for example, sang David Wingate - himself "a weary bon'd miner," and a poet born. To read his songs, "The Deil in the Pit," "The Burn in the Glen," and "My Little Wife," is as refreshing as a norland breeze.

On some occasions, the pit must be wrought night and day; and this is managed by one set of men working the day-shift, and another set the night-shift. The night-shift is always regarded somewhat of a hardship by the men, but by a change of the sets it is fairly distributed amongst them all. The wages, which are paid according to piecework, vary considerably in different districts, and are liable to fluctuation. In some cases the quantity of coal a man may put out in a day is limited by mutual consent, or in accordance with a rule of the Union; in others, the working hours are limited, each man being allowed to put out as much as he can in the stated time; and again, there are collieries at which there is no limitation either as to time or quantity. A century ago, the wages of miners, all serfs, was from 7s. to 8s. 4d. a-week. In those days candles were used in the pit, which were supplied by the masters without charge. The average wage is at present 3s. 6d. a-day. In 1851, the average was 2s. 6d.; and in 1854, it was 5s. A gradual decline then took place; and in 1858 the average was 3s.; below which sum it has not fallen, the figures for the six succeeding years being respectively 3s. 6d., 4s., 4s. 6d., 5s. 6d., and 4s. 9d. From these sums about 3d. a-day falls to be deducted for light, sharpening tools, &c. In 1871 and 1872, the wages rose to 10s. a day; and a man, with two boys, could then make as much as 20s. This was a rare and luxurious period for the colliers; but the times were too good to last. With the close of '72 came a reverse; and wages gradually declined until they reached the present average rate above stated. The relations between the Stirlingshire miners and their employers have been little disturbed by disputes as to work or wages. In the west of Scotland the case has been different - strikes being of frequent occurrence.