Knockshinnoch 7 September 1950

13 men killed by inrush of peat and moss at Knockshinnoch Castle Colliery, Ayrshire

| Knockshinnoch Memorial |

Names:

William Howat

William Lee

James Martin Love

John Irvine White

Thomas Goudie Houston

John Park McLatchie

John Smith

Samuel Wightman Rowan

James Houston

John Taylor

Daniel McFarlane Strachan

William McFarlane

John Laine Dalzell

Newspaper Reports

Click on the following links to access contemporary newspaper reports of the accident and recovery of the bodies:

- Glasgow Herald 8 September 1950 (poor quality scan)

- Glasgow Herald 11 September 1950

- Glasgow Herald 12 September 1950

- Evening Times 20January 1951 – recovery of the first 3 bodies (William Lee, John Smith & Samuel Rowan)

- Glasgow Herald 22 January 1951 – recovery of John Taylor’s body

- Glasgow Herald 23 January 1951 – recovery of 3 more bodies (identified in report on 24 Jan as James Houston, Thomas Goudie Houston & William M’Farlane)

- Glasgow Herald 24 January 1951 (report regarding messages written by men)

- Glasgow Herald 30 January 1951 –recovery of John Dalzell & William Howat

THINK OF THESE WOMEN –Three times in 24 years the sound of running feet and excited voices has brought grief to Mrs Margaret Milligan. For Mrs Milligan comes of a family whose roots are deep in the heart of Ayrshire coal seams. As a girl she was proud as any lass could be because her daddy worked down the mines. She knew nothing of her mother's anxiety—the dread lest he would not return. She was fifteen when she first learned the awful price that at times must be paid for coal. More than a hundred men were working underground that Sunday afternoon. A small fall of coal and stones occurred. Margaret's father died on the way to hospital. But in June 1930 she followed the tradition of her folk, and married a miner. For eight years her life followed the pattern of her mother's. She'd fain have had her man take a safe job above ground. But never did she hint what was in her mind. Then it happened. A cable towing men to the surface snapped. The hutches hurtled down. Twenty men were injured and five killed. Margaret Milligan's husband was laid to rest beside her father in Afton Cemetery. Slowly the wound healed. But as men continued to tramp past her door, her heart was sore. For her boys were growing up and she wondered - What would they choose? John became a plasterer. His mother breathed sigh of relief. But last Tuesday he set out for Catterick a volunteer for the Royal Signals. They had party before he left. Two evenings later siren wailed. 128 men were trapped under Knockshinnoch Castle Colliery, and among them was Mrs Milligan's other son, George. Mrs Milligan and her mother stumbled through the darkness, while ambulances and rescue vehicles streamed past. Fearfully they moved among the whispering people, past lorries, and cars and vans. Past prams even for some mothers had no choice but to take their children with them. Mrs Milligan took in the scene with unseeing eyes. She went home. She made tea. But she was moving in a dream - she knew not what she did. From eight o'clock on Thursday evening her heart was numb. One thought hammered into her brain. My son George is down there. She listened absently to the words of comfort from her mother - who knew only too well what her daughter was suffering. First, her father. Then her husband. Now, maybe, her son. It is well should think this week-end of all the Margaret Milligans in our mining communities. [The Sunday Post - Sunday 10 September 1950]

Robert Milligan died 20 April 1938

Alexander McNaught died 9 November 1924

Awarded the George Medal

Andrew HOUSTON, Oversman, Knockshinnoch Castle Colliery, Ayrshire. (New Cumnock.)

David Walker PARK, Deputy Labour Director, Scottish Division, National Coal Board. (Edinburgh.)

An accident occurred at the Knockshinnoch Castle Mine and an enormous quantity of fluid peat and moss poured into the working places, filling up some and isolating others. Andrew Houston was among the 115 men trapped and he immediately took charge and organised exploratory parties to search the accessible workings for stragglers and to find out exactly what the position was. He then assembled all the men in what he thought was the safest part. The workings in which the men were trapped were, at one point, separated by only 24 feet of coal from the disused workings of a neighbouring colliery. The telephone to the surface was still working and Houston was thus able to receive instructions as to how best the men could help in their own escape. He organised teams to drive a way through the barrier and, at the same time, rescue teams began to drive from the other side. Parts of the disused workings were heavily charged with inflammable gas, and although a connection was rapidly made it was not possible for the trapped men to leave Knockshinnoch. Efforts to clear the inflammable gas were unsuccessful and the connection between the mines had to be temporarily closed to prevent foul air entering Knockshinnoch.

The men had been imprisoned for over 24 hours when Park volunteered to go through the connection to the trapped men, using breathing apparatus, so that he could explain the efforts being made to free them. It had meanwhile become evident that it would not be possible to clear the gas from the old mine and sets of light self-contained breathing apparatus were taken below ground so that the trapped men could be brought out in relays through the foul air. Park largely organised the progress of the men out of Knockshinnoch, remaining until last to instruct each man in the method of using the breathing apparatus and to give him confidence in its efficiency. When the last of the men had been rescued he stayed to lead a Rescue Brigade in a search to make sure that no one had been left behind. Park voluntarily left his place of relative safety to join the trapped men and his presence among them at a time when their endurance had been severely tested, contributed much to the eventual success of the rescue. Houston sustained and encouraged the trapped men in his charge. His coolness and resource and the example of his steadfast courage contributed incalculably to the success of the rescue work. [London Gazette 20 April 1951]

Andrew Houston of Knockshinnoch Castle, Ayrshire.

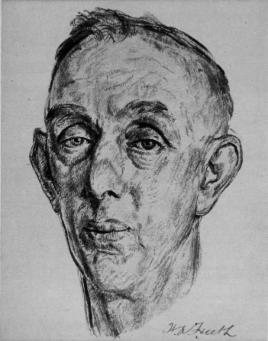

Pit Profile No 50 by H.A. Freeth

Sir Andrew Bryan’s report of the formal investigation into the Knockshinnoch Castle Colliery disaster contains this sentence, "It must be acknowledged that the leadership and example set by Andrew Houston was of a very high order."

There were many factors which contributed to the successful rescue of 116 men out of 129 from a desperate situation. To quote the report again: "This truly great result was due to the knowledge, initiative, courage and perseverance of all concerned in the rescue, and recovery operations, including the trapped miners themselves." Andrew's leadership was only one factor, but it was not an unimportant one. Andrew had this to say about it, "As for being the hero the press made out, I was just doing the job I was entitled to do. If you had picked 116 men specially to undergo that ordeal you'd not have done better than pick the men who were there."

Andrew Houston was born in a house 100 yards from where he now lives in New Cumnock, in 1894.

Straight on to Coalface - Andrew was the second son and he was followed by another boy and a girl. His younger brother was one of the 13 men killed in the Knockshinnoch tragedy. Andrew started work at 1s. 6d. a day when he was 14, at Grays Pit at Pathhead. He left school on a Friday and started work the following Monday, although it was the week before the New Year. "My parents couldn't afford to let me off even a few days; we needed every penny we could get. I went straight on to the coalface with my father, and I got a good training. Discipline was more valued in those days. We boys didn't take a meal with the men and we weren't allowed to hear their conversation, which was considered unsuitable for young ears. We sat about fifty yards away, but I don't say our ears weren't wide open to hear what was said!"

After four months at Grays he moved to Bank No. 1 Colliery, to be a pony driver at 2s. a day. His father had transferred to this colliery, too, and after a year Andrew was back on the face, again under his father.

In 1930 two important events occurred in his life, one had a tragic ending, the other affected his whole career. His first marriage ended after one year, when his wife died giving birth to twins, one of whom was stillborn, the other living only six months. The second event was his meeting with David Park, now Deputy Labour Director Scottish Division, but then oversman at Afton No. 1 Colliery. The two became friends, and David Park encouraged Andrew to get his Fireman's Certificate, which he obtained in 1932. He was appointed oversman in the same colliery in October 1937.

In 1942 he went back to Bank No. 1 as oversman and after about a year to Bank No. 6. It is important to remember these moves because his intimate knowledge of conditions at Bank No. 6 Colliery, through which the entombed miners were rescued, was of importance in organising the rescue work.

In February 1944 Andrew was appointed oversman on the back shift at Knockshinnoch Colliery, and he was holding that position at the time of the disaster in September 1950.

Andy's present wife is his best friend, he chaffs her a lot but he thinks she is one in a million. "Andy," said his wife, "has a sort of solemn face." "That," interjects Andy, "is through living with you! She was nine stone when I married her and look at her now. Maybe I got a better bargain than I thought!"

Andrew, indeed, has a solemn face, a face with heavy-lidded eyes in large eye sockets, surmounted by arched, expressive eyebrows; a face with an important nose and, to match the long proportions. It is a face appropriate to a man whose intelligent level-headedness inspires confidence.

On April 25 it was announced that David Park and Andrew Houston had been awarded the George Medal for the part they played in the Knockshinnoch rescue.

This article cannot end more appropriately than by quoting David Park's own description of Andrew's character: "Andrew is an honest-to-goodness, sincere, good-natured fellow with a modest and friendly disposition: he has a highly developed sense of humour which displays itself best, perhaps, in adversity. He is one of the most altruistic men I have ever met and I could have said that, and more, even before the disaster occurred at Knockshinnoch." [Coal, volume 5, June 1951]

Official Report By Sir Andrew Bryan

(Plans to follow shortly)

Report on the Causes of, and circumstances attending, the Accident which occurred at Knockshinnoch Castle Colliery, Ayrshire, on the 7th September, 1950

The Right Honourable Philip Noel Baker, M.P., Minister of Fuel and Power.

2nd March, 1951.

Sir,

I. Introductory

In compliance with your direction, I have held a Formal Investigation under the provisions of Section 83 of the Coal Mines Act, 1911, and under the Ministry of Fuel and Power Act, 1945, into the causes of, and circumstances attending, the accident which occurred at Knockshinnoch Castle Colliery, Ayrshire, on 7th September, 1950. The accident was due to a big inrush of peat or moss from the surface. Thirteen lives were lost and the 116 men whose escape was cut off were rescued about two days later. I have now the honour to submit my report.

By kind permission of the Ayr County Council, and at considerable inconvenience to their work, the Inquiry was held in the Council Chamber of the County Buildings, Ayr, from the 7th to the 10th November, and from the 13th to the 16th November, 1950. I desire to record my appreciation of their assistance in placing such suitable accommodation at my disposal.

The appearances at the Inquiry were as follows :-

(a) Ministry of Fuel and Power

Mr. H. R. Houston, H.M. Divisional Inspector of Mines.

Mr. E. Richford, H.M. District Inspector of Mines.

Mr. F. J. Hartwell, Safety in Mines Research Establishment.

(b) National Coal Board

Mr. R. P. Morison, K.C.

Mr. J. O. M. Hunter, Advocate.

Mr. James Allan, Solicitor.

(c) National Union of Mineworkers

Mr. Abe Moffat, President, Scottish Area.

Mr. J. A. Hall, President, Yorkshire Area.

Mr. A. Horner, General Secretary.

Mr. W. Pearson, Secretary, Scottish Area.

(d) National Association of Colliery Overmen, Deputies and Shot-firers

Mr. B. Walsh, General Secretary.

Mr. J. Limond, Agent, Scottish Area.

(e) National Association of Colliery Managers

Mr. R. G. Cochrane, Solicitor.

Professor I. C. F. Statham.

Mr. W. Moody.

(f) British Association of Colliery Management

Mr. F. A. Davies.

(g) Federation of Small Mines of Great Britain

Mr. J. Moffat.

(h) Institute of Mining Surveyors

Mr. A. Scott.

A list of the 55 witnesses examined during the course of the Inquiry is given in Appendix I, and a list of the persons who lost their lives by the accident is given in Appendix II.

II. General Information

Knockshinnoch Castle Colliery is situated in the Parish of New Cumnock in the County of Ayr and lies about 22 miles almost due east from the town of Ayr. Before the accident the colliery gave employment to about 600 persons underground and 120 on the surface and had a weekly output of coal varying from 4,500 to 5,000 tons. The output came from two seams, the Main Coal and the Turf Coal, the major portion coming from the Main Coal. The downcast shaft, completed in 1942, was ordinarily used for the winding of men, mineral and material and is 16 feet in diameter and 122 fathoms deep. The older Knockshinnoch No. 1 Pit served as the upcast shaft and also as the second exit. It lies about a quarter of a mile to the north of the downcast shaft and is 12 feet in diameter and 70 fathoms deep.

The ventilation was produced by an Aeroto fan situated at the surface at Knockshinnoch No. 1 pit and passing 65,000 cubic feet per minute with a water-gauge of 4 1/2inches. Safety lamps were used throughout the mine. The type of lamp provided for general underground use by workmen was the Oldham-Wheat Q type, 4-volt electric cap lamp. For gas testing, the workmen were issued with Prestwich Patent Protector, Type SL, magnetically-locked flame safety lamps, and the officials with Prestwich, Type No. 6, flame safety lamps, fitted with internal re-lighters and magnetic locks. Limestone dust was used for stone-dusting throughout the colliery. At Knockshinnoch Castle downcast shaft an underground pump with a capacity of 125 gallons per minute normally ran from nine to twelve hours per day, while at No. 1 upcast shaft there were two pumps, one with a capacity of 500 gallons per minute which ran for three hours per day, and a second, with a capacity of 125 gallons per-minute, which ran for twelve hours per day.

The colliery is operated by the National Coal Board, Scottish Division, and is one of fifty producing collieries, many relatively small, comprised within the Ayr and Dumfries Area. This Area is divided into three Sub-Areas, each of which, in turn, is divided into Groups. Knockshinnoch Castle was the largest of the six collieries in the New Cumnock Group in the Dunaskin Sub-Area, which comprised twenty-one collieries. The Manager of the colliery was Mr. W. C. Halliday, who was assisted by an Under-manager, Mr. B. Y. Kennedy. There was an overman, Mr. J. N. Houston, in general charge underground on the day-shift, and he was followed by a second overman, Mr. Andrew Houston, who was in charge underground on the afternoon shift. There was no overman on the night-shift. Five firemen were in charge of the working districts on each of the three shifts. Mr. J. Bone was the Agent of the New Cumnock Group. The Dunaskin Sub-Area was under the general charge of Mr. A. M. Stewart, the Sub-Area Production Manager, who was, in turn, responsible to Mr. A. B. Macdonald, the Area Production Manager. Mr. D. L. McCardel was the Area General Manager. All of these higher officials held first-class Certificates of Competency.

The Sub-Area had a Planning Department and a Surveying Department. The Planning Department employed planning engineers and planners. The Sub-Area Planning Engineer was Mr. Alex. Gardner, who held a first-class Certificate of Competency and a Mine Surveyor's Certificate. His Assistant was Mr. Donald Mackinnon, who possessed a first-class Certificate of Competency. The Sub-Area Senior Planner was Mr. J. H. Cairns, who controlled the activities of four Assistant-Planners, one for each Agent's Group of collieries in the Sub-Area. The Assistant-Planner concerned with the Knockshinnoch Castle Colliery was Mr. R. McLean, who held a Mine Surveyor's Certificate. The Sub-area Chief Surveyor was Mr. C. Stewart. His Senior Assistant was Mr. T. D. Brown. The Surveyor attached to the New Cumnock Group was Mr. R. Arbuckle, who was assisted by an apprentice surveyor, Mr. Ian Murray. Messrs. Stewart, Brown and Arbuckle held Mine Surveyors' Certificates.

As several questions at the Inquiry were directed to find out why the working of such a relatively thick coal seam as the Main Coal at Knockshinnoch Castle had begun only in recent years, it is perhaps advisable to refer briefly to the geology of the district and the story of recent developments. The somewhat isolated portion of the Ayrshire Coalfield in the New Cumnock district lies at the extreme southern edge of the coal measures and is bounded on the south by the large upthrow fault known as the Southern Upland Fault. The coalfield is unique among the coalfields of Britain in that workable seams of coal are found in four groups of the rocks of the Carboniferous Period, namely, the Barren Red Measures, True Coal Measures, Millston Grit Series and the Limestone Series. Altogether, twenty-eight seams of coal exceeding two feet in thickness have been proved and, of these, seventeen are over three feet thick and nine exceed four feet. The existence of many of these seams was unknown in the Knockshinnoch Castle Colliery Area until recent years. In particular, the existence of the Main Coal - the seam mainly concerned in this disaster - was doubted for a long time and was only finally proved in 1938.

Apart from its proximity to the major Southern Upland Fault, the New Cumnock coalfield is much disturbed by faulting which has resulted in the field being broken up into more or less detached areas, in some of which coal has been worked for a long number of years. One of the most important seams worked over the years was the locally well-known "Eight Feet". In an older colliery adjacent to the present Knockshinnoch Castle, a thick seam had been worked for several years. It was locally believed to be the Eight Feet and was so named. About 1920, however, the Geological Survey suggested that this seam was not the "Eight Feet", but was an entirely different seam, the geological position of which was about one-hundred fathoms below the "Eight Feet" in the True Coal Measures. To test the theory a borehole was put down in 1924, but the results recorded were disappointing and did nothing to alter local opinion. Some years later the views of the Geological Survey were reconsidered and it was decided that further boring was justified. A borehole was put down in 1938 and gave excellent results. It proved the existence of the Main Coal at the approximate position previously indicated by the geologists of the Survey, as well as that of three other seams of workable thickness. Further boring confirmed the existence of these seams over several square miles, thus adding many million tons of workable coal to the reserves in the area. This valuable extension of the coalfield led very soon to the planning of Knockshinnoch Castle Colliery, and the sinking of the present downcast shaft was begun in 1940 and completed in 1942.

Because of the inclination of the seams and the decision of the previous owners, the New Cumnock Collieries, Ltd., to use locomotive haulage in the main roads leading to the pit bottom, the shaft was not sunk to a particular seam but to a suitable horizon from which almost level mines or stone drifts were driven as main haulage roads to give access to the seams to be worked, especially the Main Coal. In common with the coalfield as a whole, the area of coal to be worked from Knockshinnoch Castle was dislocated by faulting and, due to these disturbances, the gradient of the seams varies from comparatively level up to 1 in 2, and in parts even steeper. In addition, the composition and thickness of the seams were subject to appreciable lateral variation. This was particularly true of the Main Coal Seam which is approximately eight feet thick and comprises three distinct coal beds separated by dirt bands, with either a strong sandstone or a relatively weak "calmstone" forming the immediate roof. When the sandstone formed the immediate roof, the full thickness of the seam was extracted, but when the roof was "calmstone" the top leaf of coal was left on. The seams worked are naturally damp and it was not uncommon for the working places to be wet.

In the district in which the disaster occurred, namely, the No. 5 Heading Section in the South Boig Area, the composition and thickness of the Main Coal remained reasonably constant. Here the seam comprised the three coal beds locally known, respectively, as the "head coal", the "breast coal" and the "bottom coal" separated by dirt bands, with a bed of "calmstone" overlying the "head coal". Above the calmstone was another thin bed of coal known as the Pennyvenie Seam, which was overlain by a bed of sandstone. A representative section of the Main Coal in the No. 5 Heading Section was approximately as follows :-

Sandstone Coal (Pennyvenie) 20 inches

Calmstone 34 inches

Head Coal 23 inches

Dirt Band 9 inches

Breast Coal 20 inches

Dirt Band 14 inches

Bottom Coal 42 inches

Fireclay 2 inches

Hard Rock

The method of working was Stoop and Room, the rooms being driven 16 feet to 18 feet wide to form stoops approximately 100 feet square. The layout of the No. 5 Heading Section, which lies to the South of the downcast shaft, is shown in Fig. 1. The direction of advance was to the south-east towards the position of the Southern Upland Fault, with the gradient steepening from I in 14 to 1 in 2 in the No. 5 Heading which was the main haulage road for the district and was the leading place. Because the calmstone was weak and difficult to support, the "head coal" was left on to form the roof of the workings. Thus, in this district, only the "breast coal" and the "bottom coal", together with their associated dirt bands, were extracted, giving a working height of about 7 feet. The coal was blown from the solid by explosives, a practice which was permitted by an exemption granted by the Divisional Inspector under Clause 6 (c) of the Explosives in Coal Mines Order. The shot-holes were bored by electric boring machines, approximately 18 holes being bored for each round of shots. The faces advanced up to 9 feet per shift, two shifts of coal-getters being employed. The coal was hand loaded on to scraper conveyors which delivered on to a series of trunk conveyors, two in the No. 5 Heading and one in the Belt Conveyor Heading. At a central loading point at the junction of this heading with the South Boig Mine, the coal was delivered into tubs which were hauled to the pit bottom by locomotives by way of the South Boig and West Mines (see Fig. 1), both of which had a gradient dipping slightly towards the shaft. In headings going steeply to the rise, e.g., the No. 5 Heading, a short shaker conveyor was used next to the face. For several days before the accident this heading had been stopped and the shaker conveyor partly dismantled.

At the neighbouring Bank No. 6 Colliery, the Main Coal is reached by a dipping drift driven from the surface, mostly in stone but partly in coal, with the gradient varying up to 1 in 3,6, The mouth of this drift lies approximately one mile to the south-west of Knockshinnoch Castle Colliery. About 1944, a district in Bank No. 6, known as the Waterhead Section, was worked to the rise by a longwall conveyor face. Subsequently the Main Coal in Knockshinnoch Castle was also worked in the Waterhead Area towards Bank No. 6, leaving a barrier of coal, 200 feet wide, between the two collieries. In order to facilitate drainage from the Knockshinnoch side, a roadway was driven into this barrier up to a point about 24 feet from the Bank No. 6 workings. A borehole was then put through the remaining part of the barrier to convey the water. It was through this part of the barrier that the escape road was driven, by which 116 of the men imprisoned by the disaster were eventually rescued.

Deposits of peat or moss occur on the surface in the immediate neighbourhood of both Bank No. 6 and Knockshinnoch Castle collieries and they are shown on the 6-inch Geological Survey Map of Ayrshire, Sheet XLI1 S. W. One such deposit was shown, part of which actually covered the place where the disaster originated. There is no previous history of an inrush of moss in this area. A few years ago, however, work had been carried on underground in Bank Colliery - of which Mr. J. Bone was the Agent at that time - where a surface peat deposit had to be probed to determine its thickness in order to comply with the General Regulations of 1920, relating to the precautions to be taken when working under moss.

III. The Accident and Events leading up to it

The accident occurred about 7.30 p.m., whilst the afternoon shift was at work, on Thursday, 7th September, 1950, when a large volume of liquid peat or moss suddenly broke through from the surface into the No. 5 Heading Section of the Main Coal Seam. The inrush started at the point where the No. 5 Heading, which was rising at a gradient of 1 in 2, had effected a holing at the outcrop of the seam beneath superficial deposits and had made contact with the base of a relatively large natural basin containing glacial material and peat. The liquid matter, rushing down the steeply inclined heading, continued to flow for some time and soon filled up a large number of existing and abandoned roadways as well as several working places, until it eventually cut off the two means of egress to the surface from the underground workings of the colliery.

There were 135 persons employed underground at the time. Six persons working near the shaft bottom quickly escaped to the surface by way of the downcast shaft before it become blocked, while 116, with all means of escape cut off, found their way inbye to a part of the mine then unaffected by the inrush, leaving 13 persons missing. The 116 men were rescued about two days later. The 13 missing men were all employed in or about the No. 5 Heading Section where the inrush began. One was the fireman in charge of the district; one was the shot-firer ; nine were coal getters employed at the face of three different working places, while the other two were concerned with the transport of coal from the district.

To develop the No. 5 Heading Section for the purpose of exploiting the area of Main Coal lying to the south of the shafts, a pair of main headings, at 100 feet centres, was driven in coal to the rise in a south-easterly direction. These headings were about 18 feet wide and about 7 feet high. Connexions were put through between the headings to form stoops about 100 feet square. One of these headings was known as the No. 5 Heading. It was used as the main haulage and travelling road for the Section and was always kept in advance of its companion heading.

A contoured development plan, which had been sent to the Manager by the Sub-Area Planning Department in April, 1950, indicated, in blue, the extent of expected progress of the workings until 1st September, 1950, and, in orange, the progress expected from then until 1st February, 1951. It was not a development plan in the sense that it established for the first time the method of working to be adopted in this Section of the colliery. It was nothing more than a progress plan based on the already established Stoop and Room system of working. But it did show that the main development headings should almost reach the conjectural position of the Southern Upland Fault and that at that stage, they would have at least 100 feet of cover from the surface. This was so because the underground contours shown on the plan - which, of course, were conjectural so far as they concerned the unworked coal ahead of the existing workings - were based on the gradient of 1 in 4 then prevailing near the face of the actual workings when the plan was made. After that time, however, as might have been anticipated in a seam rising towards a major upthrow fault, the gradient became steeper (Fig. 2) and, on the 6th July, 1950, when the last quarterly survey was made before the date of the inrush, levellings showed that the face of the No. 5 Heading was only 196 feet vertically below the surface. By this time it had become obvious to the management that the main headings would not strike the Southern Upland Fault because the gradient of the seam, which had been increasing for some time, continued to steepen until it became almost 1 in 2, and that the headings would reach the outcrop of the seam near the surface at a point somewhere south of the shafts. This fact does not appear to have been treated by the management as a matter of concern, nor as something to which the attention of the planning department should have been drawn.

For some considerable time, at least a year or two before the date of the inrush, it had been realized by the management that, if certain inbye districts of the colliery were to be fully exploited and adequately ventilated, it would be necessary to increase the quantity of air circulating underground. Eventually, in order to achieve this, it was decided to drive a new dipping drift starting from the surface to meet the underground workings and thus provide an additional airway. This drift was in course of being driven at the date of the disaster. When this drift was commenced, however, no one knew that the development headings in the No. 5 Heading Section were likely to reach the surface. But as soon as the management realized that the headings, if continued, were bound to reach the surface, the prospect of being able to drive a road in the coal to the surface seems to have appealed to them. At any rate, at one time or another during the year, the matter was certainly discussed by the Under-Manager, Manager, Agent and Sub-Area Production Manager but, strangely enough, no definite decision seems to have been made about it. The Under-Manager apparently believed that the intention was to drive No. 5 Heading through to the surface for the purpose of providing a new airway, and said so in evidence. On the other hand, the Manager said the project was considered by the Agent and the idea abandoned, whereas the Agent said, in evidence, that the matter was still under consideration a few days before the inrush occurred. Altogether, the evidence on this important matter of planning was unsatisfactory, conflicting and disappointing.

Be that as it may, No. 5 Heading and its companion heading were driven rapidly forward. Nothing untoward happened until about 10 a.m. on the day-shift of Wednesday, 30th August, when a shot was fired in the "breast-coal " at the face of No. 5 Heading by the fireman, D. Strachan, one of the victims of the disaster. This shot blew through and exposed what appeared to be a bed of stones, leaving an opening described as 2 to 2 1/2 feet wide for the full height of the "breast coal", and 4 to 5 feet deep. Water started immediately to run out of this opening but, of the many witnesses who saw it, none was able to estimate the flow with any degree of accuracy. It was best described by one witness as the amount of water which would How freely from .1 2-inch pipe. The water was clear, fresh and without odour and it was allowed to run freely down the floor of the heading. The flow of water remained fairly constant until the morning of the accident, and does not appear to have caused any undue alarm to anyone, and certainly not to the officials, from the overmen upwards. When the holing was effected, the place was stopped and no more coal was won from it. The day-shift overman, J. N. Houston, who was on duty in the Section at the time, saw the holing about 15 minutes after the shot had been fired. Several other shot-holes had been bored in the coal at the face of the heading but none of these had been fired. Water also issued from one or more of them but the various witnesses who visited the face disagreed as to the exact number. The Manager inspected the place about an hour later and very wisely decided that wooden chocks or pillars should be built to the roof to supplement the props and bars ordinarily used to support the roof, and thus make the place more secure. These chocks were built from hardwood blocks, 30 inches long and 6 inches square. Altogether, eight chocks were built in the course of the following week. Mr. Kennedy, the Under-Manager, visited the face of the heading about noon on the day following the holing, but Andrew Houston, the overman in charge of the back-shift did not inspect the face of No. 5 Heading after the shot had blown through. He had been made aware of the position by the day-shift overman who informed him that the heading had holed through "on the crop" and had been stopped. Mr. John Bone, the Agent, was also told that the heading had reached the outcrop but he did not visit the place.

On Thursday, 31st August, as soon as the No. 5 Heading had holed through, the Agent gave instructions for the underground workings to be surveyed and levelled by Mr. Ian Murray, an apprentice surveyor, to determine the exact position of the face of No. 5 Heading and its depth below the surface. The survey showed that there was about 38 feet of cover between the roof of the heading and the surface. On the same day, a survey was made on the surface by Mr. T. D. Brown, the senior assistant surveyor for the Sanquhar and New Cumnock Colliery Groups. During the course of this survey a pointed wooden peg, two feet long and two inches square, was knocked into the ground to mark the point immediately above the face of the No. 5 Heading. This peg was knocked in by Murray, the apprentice surveyor, who said that he used a blacksmith's 2-lb. hand-hammer and that the peg went in more readily than he expected for a peg of its size. But he was not curious about the reason and appears to have thought no more about it, although he did notice the ground was "a wee bit soggy underfoot ". Mr. T. D. Brown, on the other hand, who said he had walked over the ground that day taking levels and measurements, including the ground above the No. 5 Heading, said in evidence that it appeared ordinary soil. To him "it was pasture-green : nice green grass on it". It was dry weather that particular day although there had been considerable rain on previous days.

About that time, Mr. Halliday, Manager, Mr. Bone, Agent, and Mr. D. Mackinnon, Sub-Area Planning Engineer, also walked over the ground to see where the No. 5 Heading would come out if it were driven right through to the surface. Surprising as it may seem, although both Mr. Bone and Mr. Mackinnon had previous experience of workings under moss at other collieries, none of them noticed the presence of peat or moss or anything unusual in the character of the ground, or even any feature to arouse suspicion of danger.

In the meantime, as the two rise development headings underground had been stopped, the miners who had been working in them were transferred outbye to two new places on the left or dip side of the No. 5 Heading, one place being six and the other seven stoop lengths back from the face of the heading. The other set of miners in the Section was put to work in a place going to the right or rise side of the companion heading, six stoop lengths back from the face of this heading.

The flow of water from the hole at the face of No. 5 Heading appears to have remained fairly constant until the morning of the 7th September, the day of the disaster, when a marked increase in the quantity was noted. The amount was described by various witnesses as two to three times the amount previously flowing. About 9.30 a.m. the day-shift fireman, Thomas McDonald, informed the day-shift overman, J. N. Houston, about the increased flow of water. The overman went into the face of the heading and found that the hole in the coal was a little wider but the stones at the back appeared to be in the same consolidated state as when the shot had first blown through. As the water was finding its way into the outbye working places on the dip side of the No. 5 Heading the overman gave instructions to one of the oncost men to dig a gutter to confine the water to the heading. The Under-Manager arrived shortly afterwards, but, as he had hurt his knee, he did not go right up to the face of the heading, stopping about 100 feet short. He discussed the position with the overman but they seem to have been more concerned as to whether the outbye pumps would be able to deal with the increased quantity of water than with any possible danger the increase might portend. The increased flow of water carried a lot of loose coal down the heading and possibly an occasional stone or pebble, and caused a lot of trouble with the conveyor belts, the result being that very little ordinary work was done that morning. When the overman came to the surface about 3.30 p.m. he informed Mr. Kennedy, the Under-Manager, that the flow of water had not increased since 9.30 a.m. Mr. Bone, the Agent, and Mr. Arbuckle, the Surveyor, were present. He told them that the fireman had reported that two chock pillars had fallen out before the end of the shift. It appeared that the base of these chocks had been levelled on loose dirt and it would seem that the rush of water had washed away the dirt, thus loosening the pillars.

On the afternoon shift of the 7th, three sets of miners were sent to work in the places already described, oft" No. 5 Heading. The men working in the right-hand place were J. D. Houston, T. Houston and W. McFarlane. In the outbye dip-side place were J. Smith, S. Rowan and W. Lee, and in the place, a stoop length above, were J. Love, J. Murray and J. White. These men are all missing. About 6.30 p.m. the No. 5 Heading Section fireman, Daniel Strachan, sent a message saying he wished to see the overman, Andrew Houston. Houston sent word to the fireman to come out and he met him about 50 yards inbye from the pit bottom. Strachan said there had been a big fall at the face of No. 5 Heading, that it extended to a point roughly 300 feet from the return end of the conveyor and that the water had practically stopped running. Houston instructed him to go back and satisfy himself as to the condition of the Section while he went and had a look at the surface.

Houston then went over the surface and found a hole or "sit " in the ground 25 to 30 feet long and 10 to 15 feet broad and about 2 feet deep. About 6.40 p.m. he telephoned the Manager and told him about the fall and the hole on the surface. The Manager gave instructions for a fence to be erected round the hole as a right-of-way existed across the field and, as there were not sufficient men about on the surface, he told Houston to bring three men out of the pit. The Manager had been absent on leave earlier in the day but when he got Houston's message he came to the pit to see things for himself.

Houston then went underground to investigate the position in No. 5 Heading. He went along the South Boig Mine and met John Dalziel at his working place at the foot of the Belt Conveyor Heading where he was loading coal. Houston went up the Belt Conveyor Heading and at its junction with No. 5 Heading met William Howatt, switch-attendant, who worked at that point. These are two of the missing men. Houston continued up No. 5 Heading and as he reached a point just inside the return airway he felt a sudden blast of air which came down the heading. He, nevertheless, continued inbye and met J. Montgomery, another belt-attendant. He spoke to him and almost immediately J. Haddow, the switch-attendant at the tandem belt, came outbye. Haddow had seen the framework of the conveyor moving outbye and was making his way out of the pit. At this moment all three heard a "terrific roar " and the trunk belt began to move outbye down the road. Houston at once look the two men with him and turned up the heading on the rise side which leads to the bore hole from the surface, and from there made his way into the return airway to the top of Garrowscairn No. 3 Dook, From there he went across to the telephone at the end of the West Mine and sent messengers to each of the district firemen telling them to withdraw their men immediately. Houston then went out along the West Mine where he met two men, A. McLatchie and W. Walker running inbye. They had tried to go out but had found the road closed by a mass of sludge. Houston went back to the inbye end of the West Mine where he collected the firemen and their workmen.

It was then established that the following men were missing :-

Daniel Strachan, fireman in charge of No. 5 Heading Section ;

John McLatchie, shot-firer in No. 5 Section ;

William Howatt, switch-attendant;

John Dalziel, loader-attendant, and the nine miners who had been working in the three places off No. 5 Heading.

Meanwhile, a party of men under the leadership of J. Craig, Garrowscairn Section fireman, and S. Capstick, shot-firer in the Turf Coal, had gone exploring up the return airway clown which Houston had recently come. These men had gone up to see if it was possible to get out to the surface but had found all roads blocked by sludge.

Fortunately, the telephone to the pit bottom and the surface remained in working order and Houston was able to inform the Manager of the position. A second exploring party was organized under the leadership of S. Capstick, the shot-firer, to go once more into No. 5 Section by way of the return, in order to try and locate any of the missing men and to see if any road had by this time become open to the surface. This party soon returned without finding any trace of the missing men and confirmed that there was no possible way of escape in that direction. This meant that the 116 men were imprisoned.

In the meantime the three workmen who, earlier in the shift, had been directed by Houston to go to the surface to help with the erection of a fence round the subsidence, had left the pit. They went over to the hole in the field with two surface workers. This party had only just started to erect the fence when the ground in the neighbourhood began to subside rapidly. The hole rapidly extended itself, the ground flowing in from all sides towards the point where the first subsidence had appeared. Mr. W. C. Halliday. the Manager, had arrived at the Colliery about 7.30 p.m. in response to the message from Andrew Houston. He went over the surface to see the hole in the ground and at once decided to acquaint the Agent of the circumstances. He tried to telephone him but could not get in touch with him. He then returned to the field and at that time the hole started to get bigger. He sent for Cunningham, one of the men who had come up from underground, and asked him if he would go back down the pit and try and catch the overman and tell him that the subsidence in the field was getting bigger. Well knowing the danger, Cunningham at once volunteered.

At the Inquiry, in answer to questions the Manager described the movement at the crater as follows:-

A. "The grass had gone down out of sight".

Q. "Was there a hole right down?"

A. "There was a hole - a deep hole ".

Q. Had it gone bodily or had it tapered in?"

A. "It turned in like this (indicating). The grass broke when it turned in ".

Q. "A sort of vortex ?"

A. "Yes, a sort of circular moving and tore the grass ".

Q. "You have seen water running out of a bath or basin when the plug is pulled out; you get a vortex?"

A. "It was something like that".

The Manager then went across to the pit and when he got there received a message from Cunningham at the pit bottom saying that, although he had made several attempts, he could not get up into the Section because the roadways in the pit had filled with sludge which had driven him back to the pit bottom. The Manager instructed him to telephone to the men in the inside to get word to the firemen in each of the Districts and tell them to withdraw their workmen and bring them outbye. He then went underground himself and tried to get inbye, accompanied by Cunningham. They found the road blocked to the roof with mud near the junction of the North level and the West Mine. They tried to get up the return airway but found it also blocked with mud. Mr. Bone, the Agent, then came down the pit and it was at that time that Andrew Houston, the overman, telephoned out saying that he had all the workmen with him except those from No. 5 Section. The Manager and Cunningham made several more determined efforts to get inbye but found it quite impossible. An attempt was made to deal with the mud at the pit bottom by filling it into hutches and winding it up the pit, but the sludge kept on slowly oozing outbye and in the end reached the pit bottom and further efforts to deal with it had to be abandoned. In the course of the next 24 hours or so the sludge rose 16 feet up the winding shaft.

In the meantime the subsidence on the surface (Plate I) had increased until the area involved was approximately 2 acres in extent (Fig. 3), and 40 to 45 feet in depth. In an attempt to prevent the moss or peat running into the pit, bales of straw and hay, trees, pit timber and hutches were thrown into the crater (Plate II). This effort was entirely unavailing though some of these articles were later found in the workings where they had been carried by the flow of peat. The assistance of several Fire Brigades was obtained, portable petrol pumps were installed at strategic points round the subsidence and fresh ditches were dug in order to prevent or reduce the amount of surface water flowing into the crater. In addition, several surface drains and a burn were dammed and the water was pumped into the river Afton. Messrs. Wimpey, Public Works Contractors, were called in to secure the sides of the hole and to take such steps as were possible to make it safe for an exploring party to enter the exposed roadway at the bottom of the subsidence. This work actually started at 7 a.m. on the 8th September. By 4 p.m. on Sunday, 10th September, a party of six men descended into the workings from the crater, followed by a second party at 10 p.m. but they found that the two main headings were completely blocked with moss at a point about 800 feet down.

IV. The Rescue

As has already been indicated, the overman, Andrew Houston, had collected 115 workmen in the neighbourhood of the inbye end of the West Mine. It was apparent that the greater part of the roadways between the shafts and this point were blocked with enormous quantities of sludge and that a very long period of time, probably running into months, would be required in order to reach the men by clearing a passage along these roads.

News of the disaster was conveyed at once to the higher officials of the Ayr and Dumfries Area of the National Coal Board, representatives of the mine-workers and of the Mines Inspectorate and many of them were on the scene within a very short time. The position was discussed and it soon became obvious that the only hope of rescuing the imprisoned men was to make a connection through the narrow barrier, already described, between Knockshinnoch Castle and Bank No. 6 at the point where the water had been pumped through. The overman, Andrew Houston, in charge of the imprisoned men was informed of the position by telephone and he was instructed to explore the Waterhead Dook from his side. This was done and it was found that the roadways were open and that the place containing the borehole was accessible.

The following arrangements were then made on the surface:-

(a) A Headquarters Base was established at Knockshinnoch Castle, where communication by means of telephone was available between the trapped men, Bank No. 6 office, and the surface crater.

(b) An operational base was established at Bank No. 6 Mine which maintained contact between the underground base and Knockshinnoch Castle Headquarters. The Post Office telephone at this base was reserved for outgoing calls and incoming priority calls by arrangement only.

(c) High officials of the National Coal Board were detailed to take all practical measures to minimize the inflow from the hole on the surface to the Knockshinnoch Castle Main Coal Workings.

In the meantime, rescue apparatus had been made available at Knockshinnoch Castle from Kilmarnock and Auchinleck Rescue Stations and calls were sent out for all the local rescue brigade men. The Central Rescue Station at Coatbridge had also been warned to stand-by in readiness. The rescue apparatus was despatched to Bank No. 6 Mine where a room was made over as a surface operational base.

In view of the distance inbye (about two miles) and the lack of haulage facilities, volunteers were asked to stand-by to act as carriers to the rescue teams, i.e., one volunteer to carry the apparatus inbye and wait until the rescue man did his turn of duty, and then carry the apparatus to the surface again. The rescue operations fall into three stages as follows:-

STAGE 1

At 11.30 p.m. on 7th September, Mr. G. Rowland, H.M. Inspector of Mines, accompanied by Mr. McParland, Manager of Bank No. 6 Mine, the Superintendent and his Assistant from Kilmarnock Rescue Station, together with two local brigades equipped with Proto apparatus and Novox Revivers, descended Bank No. 6 Mine with the instruction to make a preliminary inspection of the abandoned Main Coal workings already described. In the meantime, Mr. A. Macdonald, Area Production Manager, had staffed the operational base at the Bank No. 6 office. The Coatbridge Rescue Station Superintendent, who had arrived with equipment and teams, was detailed to take over the responsibility of making and maintaining a rescue team rota as the men became available.

Mr. Macdonald and Mr. Richford, the District Inspector of Mines, then descended the mine at 2.30 a.m. on 8th September, and met Mr. Rowland and his party who were returning to report, and received the information that the teams had been able to travel along the old road inbye the point where the connection to Knockshinnoch Castle would have to be made. The roads were full of firedamp and the inspection had been made with the use of apparatus, a fresh-air base being established in cross-cut " X ". (See Fig. 1.)

As electricians, engineers and voluntary workers were now available, detailed arrangements were made on the spot for the installation of auxiliary fans in an attempt to dear the accumulation of gas. Fan No. 1 (Fig. 1), was a booster fan exhausting from the section when it was in production. The use of this fan had never been discontinued, as it maintained ventilation to an auxiliary pump. The first forcing auxiliary fan to be installed is shown as Fan No. 2 on the plan. By midday on Friday, 8th September, the gas had been cleared about 300 feet up the right-hand roadway, and hope of clearing the remaining firedamp appeared good. Rescue men were used to extend the canvas tubing from the auxiliary fan as the gas cleared, but the position fluctuated considerably and very soon it became common procedure to have to send them forward to shorten (by removing the last extension piece) the fan tubing in order to consolidate progress.

A sound powered microphone obtained from Coatbridge Rescue Station enabled telephonic communication to be maintained from the underground operational base through a normal pit 'phone, to the surface base at Bank No. 6. About 4 p.m. on Friday, 8th September, when the telephone to the imprisoned men began to show signs of weakening, the trapped men on the Knockshinnoch Castle side were instructed to start making a passage through the barrier which separated the two workings. They were told to halt just short of the old road lest the firedamp from Bank No. 6 should foul their atmosphere which was then reported to be free from firedamp.

It became obvious, however, that more urgent measures would have to be adopted if the gas from Bank No. 6 side was to be cleared in time. With this object in view the following arrangements were made:-

(1) Fan No. 1 was to be replaced with one of greater capacity (the one subsequently installed had a capacity of 12,000 cubic feet of air per minute).

(2) Fan No. 2, which was of 8,000 cubic feet of air capacity, was to be duplicated by Fan No. 3, the two to run in series.

(3) All the air available from the Bank Mine surface fan would be directed into the operational area by the erection of stoppings placed at suitable points.

Stupendous efforts saw these changes in the ventilation arrangements made in the course of four or five hours, but still no real progress was made. Throughout the whole period, rescue teams had been passing to and fro along the gassed-out roadway, effecting repairs, erecting a stopping marked "Y" on Fig. 1, and erecting a temporary stopping "Z" in bye the point of contact with the Knockshinnoch Castle workings.

When the trapped men had received instructions to commence making a passage through the barrier, they were warned to keep a small hole in advance and to watch the direction of the air. If the air came from Bank No. 6 into the Knockshinnoch Castle workings, the hole was to be immediately plugged and they were to await further instructions. Fortunately, however, when the hole was made, it was found that the air travelled from Knockshinnoch Castle to Bank No. 6 side and so instructions were then given for the hole to be enlarged to enable rescue brigade men to pass through and take food and drink to the trapped men. The flow of air through the hole from Knockshinnoch to Bank did not persist, however, and after a while died away except for a slight ebb and flow. But as a precautionary measure, the hole was screened to isolate the two ventilating systems as far as practicable.

In the meantime arrangements had been made for a rescue brigade team to carry food and drink through to the trapped men. On the night of Friday, 8th September, the overman, Andrew Houston, went to the holing to greet the first rescue team and conduct them to the trapped men. Up to this time, all telephone messages from Andrew Houston to the surface had indicated that the atmosphere was free of gas in the Knockshinnoch workings. But when Houston was on his way back with the rescue team, he found men erecting a brattice at the top of the Waterhead Dook and two of the trapped firemen told him that gas was collecting there. The trapped men had previously been told, of course, of the presence of a large body of gas in the roadway on the Bank side and of the efforts that were being made to clear it so that they could walk out, but this was the first indication of gas on the Knockshinnoch side. This news was kept back from the main body of the trapped men lest it should adversely affect their morale. But, quite naturally, with the arrival of the food and rescue brigade, the trapped men thought their hour of rescue had come and that they had now nothing more to do but to walk out with the rescue team. Houston had to explain to them that the gas on the Bank No. 6 side had not been cleared and that it might be a considerable time yet before they could be rescued. The food and drink and the visit of the rescue team had cheered them greatly, but the news that they must still wait was a bitter disappointment.

It was now apparent to those in charge of the rescue operations that the clearing of the gas from the Bank No. 6 workings presented a major problem and consideration was now given to the possibility of the trapped men having to be brought through the irrespirable zone by means of self-contained breathing apparatus. With this possibility in view, instructions had previously been given to collect as many sets of Salvus apparatus as possible from all readily available sources.

This apparatus, like the Proto apparatus used by the rescue brigades, is of the self-contained or regenerative type. In essentials it is a closed circuit device working on the principle that the same air can be breathed over and over again if, after each breath, the carbon dioxide is extracted from the exhaled air and the requisite amount of oxygen is restored. The oxygen is carried in a steel cylinder containing 95 litres when charged to a pressure of 1,800 lb. per sq. in. From the cylinder the oxygen passes via a main and reducing valve, adjusted to deliver two litres per minute, into a breathing bag and thence through a carbon dioxide absorbent and a cooling medium to a mouth piece of the usual type. As it is intended only to be used for half-an-hour, it is both simpler and lighter than the Proto, which is designed for two hours use, and when fully charged it weighs only 18 lb.

Following an inspection and a careful review of all the circumstances in the early morning of Saturday, 9th September, the fact had to be accepted that despite all efforts, no real progress had been made in clearing the Bank side roadways of gas. Nor was there any immediate prospect of substantial progress. A scheme was then formulated to use rescue teams consisting of six members, each team to escort three of the trapped men wearing Salvus apparatus, through the irrespirable zone. It was estimated that it would take forty hours to evacuate all the trapped men in this manner ; but since all the telephone messages to the surface from the trapped men up to this time indicated that fresh air was still circulating and now that it was known that the men could be supplied with food and drink, this long period, although regrettable, caused no undue alarm.

It was fully realized, of course, that to put such a scheme into operation would be a risky venture, since the trapped men were wholly unaccustomed to wearing rescue apparatus, and the hope was that the gas filled roadways could be cleared and the men would be able to walk out in fresh air.

Soon alter the holing was made between Knockshinnoch and Bank, disquieting rumours began to circulate about the state of mind of the trapped men. They were restless and puzzled by the delay in their release ; and rumour had it that some of them, especially among the younger element, were talking about making a suicidal dash for safety through the gas-filled roadways. At this juncture, Mr. D. W. Park, Deputy Labour Director of the Scottish Division of the National Coal Board, who had arrived late on the night of Friday, 8th September, suggested to Lord Balfour, Chairman of the Divisional Board, that it might be a good thing if someone put on a Proto apparatus and went through to join the trapped men in order to explain the position fully to them, tell them about the difficulties being encountered and all that was being done to effect their release. Mr. Park volunteered his services for this purpose. As a boy he had worked in the pits in New Cumnock and at one time had been the captain of the local rescue brigade. Subsequently he had also gained experience as a member of the permanent brigade attached to the Houghton-le-Spring Fire and Rescue Station in County Durham. It so happened that the brigade men at this Station were also trained as firemen and thus he also had experience in the use of the Salvus apparatus which was then used for rescue purposes during fire-fighting on the surface. Moreover, he knew many of the imprisoned men personally, including Andrew Houston, whom he felt he could help in his efforts to control the men. His offer was accepted on condition that he came back out after talking to the men and, following a medical examination for fitness, he joined a rescue brigade team which entered the Knockshinnoch workings at 3.40 a.m. on Saturday, 9th September. His appearance was warmly welcomed. As Andrew Houston said in evidence : "Well, I don't think another man breathing could have come in that would give me more confidence than Mr. David Park".

Mr. Park called the men round him, told them all that was being done to rescue them, calmed their fears and generally restored their morale which was being severely tested, and thus assisted the overman to restore discipline. His action was in a large measure responsible for the ultimate safe rescue of all the entombed men.

After addressing the men, he had a look round and found that the atmospheric conditions were far from satisfactory. Firedamp was making its appearance in the neighbourhood and the percentage was steadily increasing. He instructed the captain of a rescue team to inform those in charge of the rescue operations at the fresh air base that the condition of the ventilation in the Knockshinnoch workings was quickly deteriorating and was much worse than he could intimate over the telephone in the presence of the trapped men. There was from 3 to 5 per cent, of firedamp in the general body of the air at the telephone and, unless something was done very quickly, he was afraid it would be too late.

It was now realized by those in charge, that drastic measures would have to be taken at once and a new scheme was drawn up forthwith by the officials then in charge of the advanced fresh-air base, Messrs. MacDonald, Richford and Stewart. This was to form a "chain" of rescue brigade men along the whole length of the gas filled roadway on the Bank side who would pass sets of Salvus apparatus through to the trapped men. A rescue team would enter the Knockshinnoch workings and instruct the men in the use of the apparatus, fit it on them, and pass them out along the "chain". Mr. Stewart, the Sub-area Production Manager, returned to the surface to report the proposal and to request that a general call be made for additional trained rescue brigade men from Lanarkshire to enable the scheme to be put into operation with the least possible delay. Although they felt that the proposals were not in accordance with the Rescue Regulations, the principal officials on the surface agreed, but with grave misgivings, and about midday on Saturday, 9th September, instructions were given to put the scheme into operation.

STAGE 2

By 12.30 p.m. on Saturday, 9th September, there were five rescue teams present at the main fresh-air base. Ample reviving apparatus, stretchers, blankets and first-aid men were available, as well as two doctors with medical supplies. One of the imprisoned men was in a very weak state and could only be brought out on a stretcher. A team was sent through to give the sick man an injection provided by one of the doctors.

It was then decided that it would give the trapped men a good deal of confidence in the use of the Salvus apparatus if the sick man was rescued. A team was sent in with a stretcher, two sets of Salvus apparatus and blankets at 12.30 p.m. At 2.45 p.m. the sick man was brought to the fresh-air base. By this time, owing to various delays and incidents, all five teams had been used and there was a further two hours' delay before sufficient teams could be assembled at the base to enable the main "chain" operation to be attempted.

STAGE 3

About 5 p.m., the position was as follows:-

(1) Eighty-seven sets of Salvus apparatus, obtained mainly from Fire Service Stations, had been carried from the surface and deposited at the advanced fresh-air base, together with 100 spare cap lamps ; and more Salvus sets were on the way.

(2) A "chain " of men, at intervals of a few yards, extended from the advanced fresh-air base to the main base where the Doctors, with their equipment, were stationed, together with 30 volunteer stretcher bearers.

(3) Food, water and hot tea were available at both bases.

(4) One rescue team was held for emergencies at the main fresh-air base, where they were briefed in their duties by an Instructor from Coatbridge Rescue Station. Instructions were given that this team was not to go to the advanced fresh-air base until a fresh team from the surface arrived at the main base.

(5) One team was kept at the advanced fresh air base, being finally briefed on their duties so that they thoroughly understood the operation being attempted. As a fresh team arrived from the main base, the earlier team was sent in to the operational zone.

The main operation was started in the following manner. A team of permanent rescue men from Coatbridge Station was instructed to proceed direct to the Knockshinnoch Castle side, disconnect their apparatus, do all they could 10 build up the morale of the trapped men, and explain both the general plan of action and the use of the Salvus apparatus before fitting it to each man and .ending him out. They were to remain on this job without relief if possible. The members of the team took in Salvus apparatus and spare electric cap lamps to be used in the event of the lamps of the trapped men being exhausted. This team was informed that further supplies of Salvus apparatus would be passed to them by the other rescue brigade men who would be forming the "chain" through the irrespirable zone.

Immediately afterwards four other teams were sent off, also carrying Salvus apparatus and spare lamps, with instructions to pass them forward to the Coatbridge Brigade on the Knockshinnoch Castle side. They were then to establish the "chain" whereby the remainder of the Salvus apparatus and spare lamps could be passed from the advanced fresh-air base through to the trapped men.

All teams were briefed on the following lines:-

(a) That the intervals in the " chain " were to be shortened as fast as trained rescue brigade men became available.

(b). Each new team was to go to the head of the "chain," i.e., the end nearer the Knockshinnoch Castle workings, so that rescue men with decreasing reserves of oxygen would be placed down the "chain" towards the advanced fresh-air base.

(c) In the event of any rescue man using more oxygen than the remainder of his team mates, he was to retire to the fresh-air base as an individual, but the remainder of the team were to remain in as long as possible.

(d) Stretcher cases were not to be attempted unless authorized from the advanced fresh-air base.

(e) Definite instructions were given that, if a man wearing Salvus apparatus collapsed, they were not to do anything to impede the general scheme of evacuation.

(f) As it took twenty-five minutes for a team to travel from the advanced fresh-air base to where the trapped men were assembled, as a guide for their personal safety, each rescue man was told to allow himself sufficient oxygen to cover the period for his retirement.

The overman in charge, Houston, drew up a rota regulating the order in which the imprisoned men were to be taken out. He decided that the older men should go first, but as the strain of waiting eventually began to tell on some of the younger members, many of them were allowed to go before all the older men had gone.

As the operation proceeded, two doctors, Dr. Sharp, H.M. Medical Inspector of Mines, and Dr. Bannatyne, of Ayr County Hospital, remained at the advanced fresh-air base, whilst three others, Drs. Gooding, Fyfe and Watson, remained at the main fresh-air base. All the rescued men were medically examined at the underground fresh-air base before they were allowed to proceed outbye to the surface. About 8.15 p.m., the overman, Andrew Houston, was instructed to come out, leaving Mr. Park in charge of the remaining men. His presence was required in order to ascertain, as far as might be possible, the last known positions of the missing men.

Towards the end of the evacuation it was reported by one of the returning rescue men that one of the trapped men, who suffered badly from asthma, had attempted to come out twice but had been forced to return. It was decided that he should be brought out on a stretcher. The doctors were informed and they suggested the man should be given certain pills and another injection which they could provide. A rescue brigade man was instructed on this procedure and given a team who took in a stretcher for the express purpose of dealing with this case. The man was brought out safely without any further trouble.

The last of the trapped men reached the advanced fresh-air base at 12.5 a.m. on Sunday, 10th September, the complete operation having taken approximately eight hours. Stage three was thus completed. Twenty brigades had been used in the evacuation. Excluding the Coatbridge Brigade which remained inbye throughout the whole operation, six brigades were constantly maintained within the danger zone which extended over a distance of 880 yards, the rescue men being spaced at intervals of twenty yards or so. This arrangement gave great encouragement to the men wearing the Salvus, an apparatus to which they were unaccustomed, as they made their way outbye to the advanced fresh-air base.

When the sets were brought in by the rescue brigades, Mr. Park took the precaution of examining them before they were fitted to the workmen. He was directly responsible for quite a number being discarded as defective for various reasons. Had this precaution not been taken it is more than likely that there would have been several casualties among the escaping men. In order to reduce the load, and at the same time to enable rescue men to bring in more than one Salvus set at a time, each Salvus apparatus was removed from its box-container. In transit over the rough ground and through the very restricted area of the connecting road, some of the sets unavoidably received rough treatment and, in consequence, many of them were leaking, thus considerably reducing the oxygen reserve.

When the last of the men had been rescued, Mr. Park organized a search with a rescue brigade to make sure that no one had been left behind. He was the last man to leave. There is no doubt that his action in joining the trapped men and his courage, calm demeanour and initiative in the face of a very ugly situation largely contributed to the success of the rescue operations. By voluntarily joining the trapped men, David Park deliberately took a very serious risk. Had the atmospheric conditions inside the Knockshinnoch Castle workings deteriorated faster than was actually the case - and it was always a possibility - he would have found it morally impossible to put on his breathing apparatus and leave the men. Nor could he be certain at that time that the moss would not take a fresh burst and overwhelm the whole party. Although the movement of the moss seemed to have slowed down at the time he descended the mine, there could be no guarantee that it might not surge forward again or even appear from an unsuspected direction.

When the overman, Andrew Houston, reached the surface he was able to indicate to those directing operations the places where the missing men had been working, or were last seen, prior to the inrush. Andrew Cunningham, the conveyor shifter, had already described to them where he had last seen two of the missing men, William Howatt and John Dalziel, in No. 1 Heading, and how sludge had burst into the outbye end of the South Boig Mine, cutting them off from the shaft. Moreover, the limits of the sludge as found by the trapped men were also known, as well as the steady deterioration of the state of the atmosphere in the West Mine area up to the time when the last of the trapped men left. In addition, an estimate of the volume of the crater had been made in order to judge the probable extent of the spread of the sludge underground. It was felt, too, that had any of the missing men escaped the inrush and taken refuge in the workings on the rise side of the No. 5 Heading, they would have been found by the exploring parties from the trapped men and would have been rescued along with them.

From a consideration of all this information, those responsible for directing the rescue operations, in consultation with representatives of all parties, came, with regret, to the inescapable conclusion that if, by chance, any of the missing men had not been overwhelmed by the inrush, they were bound to have reached a part of the mine which was not only too remote for rescue brigades to reach from the fresh-air base in Bank No. 6 workings but was, in any case, inaccessible. In consequence, after the 116 men from the inbye end of the West Mine had been brought out safely to the fresh-air base in Bank No. 6, the decision was taken, and rightly in my view, that no more rescue brigades should be sent in through the "escape road " and that efforts should now be concentrated on an attempt at further exploration by way of the "crater ", since the exposed end of the No. 5 Heading was seen to be open. It was thought that it might just be possible to get far enough down the No. 5 Heading and find an open road to the rise off the heading which would give access to the inbye workings in which a further search could be made for the missing men.

As previously described, work had begun to make the crater safe on the morning of the 8th September, and by the night of Sunday the 10th, two exploring parties had entered the workings and reached a point 800 feet down the No. 5 Heading. Unfortunately, heavy rain persisted and made still worse the already precarious state of the sides of the crater: masses of moss were slowly but continually closing in on the opening into the No. 5 Heading. This state of affairs, especially when one bears in mind the fact that the heading lay on a gradient of 1 in 2, that all its roof supports had probably been swept out and that with the subsequent falls it was now probably 13 to 14 feet high, rendered exploration in the heading a most dangerous and difficult affair.

In the meantime, exploration from the upcast shaft had shown that all roads leading inbye from it were blocked to the roof with peat, and that little or nothing could be done from this side. Efforts were also continuing to clear the Knockshinnoch Castle shaft, but here again it was realized that progress must be very slow indeed.

By Monday, 11th September, the position at the crater was such that a meeting was held of the representatives of all parties at which the decision was made that no further work should be carried out underground from the crater until its sides and the entrance to the No. 5 Heading were properly secured. By this time it was felt that there could be no hope of reaching or rescuing any of the 13 missing men and that there was no justification for risking loss of life among the rescuers. Subsequent events have served to confirm that the decision was correct.

Although the Salvus was not an apparatus approved under the Rescue Regulations for use underground in mines, the decision to use it was not only triumphantly justified by the results but was right in principle. I do not think the Regulations did prohibit the use of this apparatus in the way in which it was used in this accident, but there is no doubt that the persons who had to take the decision had considerable misgivings as to whether they were breaking the law. A feeling was expressed that it was neither fair nor desirable that, at a time of emergency, such persons should be placed in this position.

I am in full sympathy with this feeling but it seems to me that the matter goes much deeper than these particular Regulations, right down, in fact, to the sanctity of the whole safety code in crises of danger when lives are at stake to be saved and, oft-times in that endeavour, to be risked too. There are many statutory requirements drawn in strict and absolute terms, full compliance with which in times of emergency would seriously hinder the saving of life.

The safety code is for the normal working operation of the mines and it cannot be observed in all respects in these crises : risks are inevitable and in some respects "necessity knows no law". In my opinion it is best left at that. Whatever might be done to protect those who bear these heavy responsibilities, their actions would still have to be guided by the circumstances of the occasion. I do not think it is possible to frame a provision which would give the necessary wide contingent liberty while providing adequate safeguards against ambiguity and abuse. I believe that an attempt to make precise something that in its nature cannot be precise would defeat its own ends, and sometimes perhaps make things even more difficult than they are now for those concerned.

V. Comments

(a) On the Sequence of Events at the Face of No. 5 Heading before the Inrush

Whilst all parties were agreed that the cause of this disaster was an inrush of liquid moss, the immediate sequence of events before the inrush can only be a matter for conjecture. Taking into consideration all the available evidence I think what happened was as follows :-

In dealing with immediate events it is also necessary to visualize happenings in ancient glacial times. The No. 5 Heading was driven up towards the outcrop and eventually reached it at or near the base of a relatively large hollow which had been scooped out in the softer parts of the exposed coal bearing rocks by glacial action in ages past. This hollow, which was lined with glacial boulders, gravel and sand, had formed a natural receptacle in which water accumulated. In the course of time a layer of mud accumulated on top of the deposit of boulders, sand and gravel, and in this mud, vegetation grew round the edges of the stagnant waters of the pond. In the course of time as the vegetation grew and died off, the hollow became filled with peat resting on a layer of mud. Traces of all these deposits can still be found round the inner sides of the crater left in the field after the inrush. Fig. 4 shows a diagrammatic or reconstructed section through the ground at the position of the crater as it would appear before the inrush. Whilst this section may not be strictly accurate, I think it does give a fair picture of the nature of the ground prior to the accident.